How To Customize Die Transfer Carts For Specific Industrial Needs

What Is Die Transfer Cart

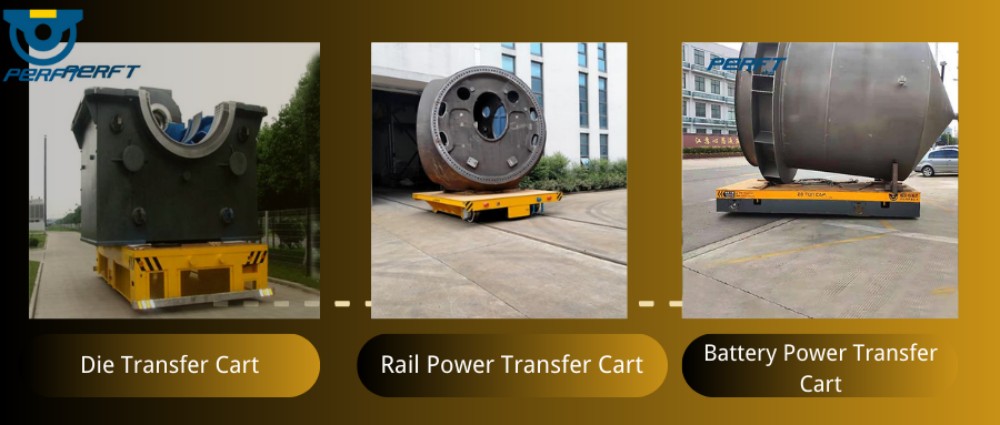

A specialized industrial vehicle called a die transfer cart, often referred to as a die handling cart or a die transfer trolley, is made to transport heavy items, most notably dies and molds used in manufacturing processes. These carts are frequently employed in a variety of industries, including the transportation of large, heavy tools or equipment and the steel and metalworking sectors.

At Perfect, we recognize the value of tailoring our products to satisfy the particular needs of various industries as a top producer in the material handling field. In this thorough article, we’ll go through how to modify die transfer carts to meet unique industrial requirements, focusing on the steel and manufacturing sectors. Our objective is to offer you the best solutions that increase effectiveness, safety, and productivity by addressing your specific challenges and preferences..

Recognizing Your Specific Industrial Needs

We start by carefully comprehending the requirements of your sector in order to produce the ideal die transfer cart that is in line with your unique requirements. In order to obtain vital information, such as load capabilities, transfer lengths, floor conditions, and any particular safety laws pertinent to your industry, our devoted team of engineers and consultants will work directly with you.

Customizable Options and Features

In order to customize our carts to meet your demands, at Perfect, we provide a wide selection of configurable features and options. This comprises different power supply options (battery-operated, cable reel, buabar or low voltage rail), configurable platform sizes, and various steering techniques (manual, automatic, or remote-controlled).

Solutions for Specialized Load Handling

Transporting bulky, oddly shaped loads is common in the industrial and steel sectors. We can include unique load handling systems, such tilting platforms, changeable height settings, and specialized clamping mechanisms, to satisfy such demands, assuring secure and safe material transfer.

Additional Safety Features

In industrial environments, safety is of the utmost importance, and our die transfer carts are fitted with cutting-edge security measures. To offer the highest level of protection for your operators and equipment, options include proximity sensors, emergency stop buttons, anti-collision systems, and warning alarms.

Selection of Materials and Durability

Longevity is crucial in industrial settings with high demands on equipment. Our customized die transfer carts can resist severe use by utilizing premium materials like high-strength steel and durable components, which lowers downtime and maintenance costs.

Customization Options for Table Style

A summary of the Perfect Die Transfer Carts’ customizability choices may be found in the table below:

Customization Option Features and Benefits

| Customization Option | Features and Benefits |

| Adjustable Platform Size | Accommodates various load dimensions |

| Power Supply Options | Choose from battery, cable reel, busbar or low voltage rail |

| Steering Mechanisms | Manual, automatic, or remote-controlled steering |

| Specialized Load Handling | Tilt platforms, adjustable height, specialized clamps |

| Enhanced Safety Features | Proximity sensors, emergency stop, anti-collision systems |

| Durable Material Selection | High-strength steel, robust components for longevity |

Workflow and Efficiency Optimization

We strive to streamline material handling procedures and decrease downtime by developing die transfer carts to fit your operation. The specialized features guarantee seamless interaction with your current infrastructure, boosting overall productivity.

Solutions From Perfect Die Transfer Carts That Are Seamlessly Integrated

With decades of expertise, we have refined our abilities to provide our clients with customised solutions. We pledge to offer specialized and perfectly fitted equipment for your industrial operations by integrating your brand name with our die transfer carts.

Using Custom Die Transfer Carts for Optimal Industrial Solutions as an Example

Imagine that you are in charge of production at a busy auto factory. Your assembly line produces a wide variety of car parts, each requiring unique dies and molds. Your productivity goals are being impacted by the present manual cart material handling process’ bottlenecks and inefficiencies. It’s time to investigate a more individualized method of material handling by modifying Perfect die transfer carts.

Step 1: Understanding Your Unique Industrial Needs

You arrange a meeting with the Perfect die transfer carts professionals to go through your unique needs. They pay close attention as you describe your difficulties, such as fluctuating load capacities, separations between workstations, and particular safety standards that are relevant to your sector. They take detailed notes and ask probing questions to fully comprehend your industrial demands.

Step 2: Customizable Features and Options

Perfect die transfer carts team has developed a variety of customisable features based on your conversations in order to meet your specific requirements:

a. Adjustable Platform Size:

You claim that your dies and molds are available in a variety of sizes. You may be confident that the professionals’ carts can be made with flexible platform sizes, allowing for the seamless accommodation of various load dimensions. This adaptation enables effective material handling and does away with the need for additional carts.

b. Power Supply Options:

In order to improve mobility on your busy production floor, you mention during the discussion that you are interested in battery-operated carts. The group presents the advantages of battery-operated die transfer carts, highlighting how they provide flexibility and agility in travelling the plant without being constrained by cable lengths.

c. Steering Mechanisms:

You need carts that can adapt as your plant has a combination of open and tight spaces. The experts explain the remote-controlled steering option and assure you that it will make it easier to handle the cart in confined situations while manual steering may be employed in more wide settings.

Step 3: Specialized Load Handling Solutions

Your factory manufactures intricate, specialized automobile parts. To meet your unique demands, the specialists recommend the following customized load handling solutions:

a. Tilting Platforms:

The team advises using tilting platform die transfer carts to optimize the loading and unloading of your complicated dies. By enabling exact die positioning, this feature lowers the possibility of damage and guarantees efficient handling.

b. Adjustable Height Settings:

You mention the necessity for die transfer carts with configurable height settings due to the fact that different production lines operate at various levels. To eliminate the need for manual changes and improve throughput, the experts advise personalizing the carts to match the various workstation heights in your office.

c. Specialized Clamping Mechanisms:

The professionals introduce unique clamping mechanisms after realizing how crucial it is to secure unevenly shaped dies. This feature minimizes the danger of damage while ensuring that your priceless machinery is sturdy and secure during shipment.

Step 4: Enhanced Safety Features

In your plant, safety is of the utmost importance. The professionals outline several safety elements that might be added to your personalized die transfer carts:

a. Proximity Sensors:

Proximity sensors are built into the carts to prevent collisions with other pieces of machinery or people. In order to prevent accidents, these sensors identify obstructions in the cart’s route and automatically stop the vehicle.

b. Emergency Stop Buttons:

You love how the carts’ emergency stop buttons are simple to reach. According to the experts, these buttons offer an immediate and effective way to stop cart movement in an emergency, assuring the safety of your workers.

c. Anti-Collision Systems:

The experts reassure you that anti-collision systems will prevent collisions between carts as your business uses many carts at once, increasing material flow and enhancing workplace safety.

Step 5: Durability and Material Selection

You voice maintenance and durability worries. Perfect Die Transfer Carts feature high-strength steel frames and components, the experts say with confidence, ensuring robustness and lifespan even under difficult circumstances. The carts will function well with little maintenance needed, reducing downtime and raising your overall production.

The manufacturing and steel sectors receive custom solutions from Perfect die transfer carts that are catered to their unique industrial requirements. We strive to increase workflow effectiveness and productivity by customizing our carts with cutting-edge technologies, enhanced safety, and robustness. You can rely on us to be your partner in optimizing your material handling processes and providing a smooth and effective industrial experience.