Rail Transfer Cart: Common Problems And Maintenance

Low voltage rail transfer trolleys have high requirements for track laying and require insulation treatment. They are suitable for medium and long-distance transportation. The frequency of use is not restricted, but they cannot be used in flammable, explosive, waterlogged, dusty, and iron filings-intensive environments. So what are the common problems with low voltage rail transfer carts in daily use?

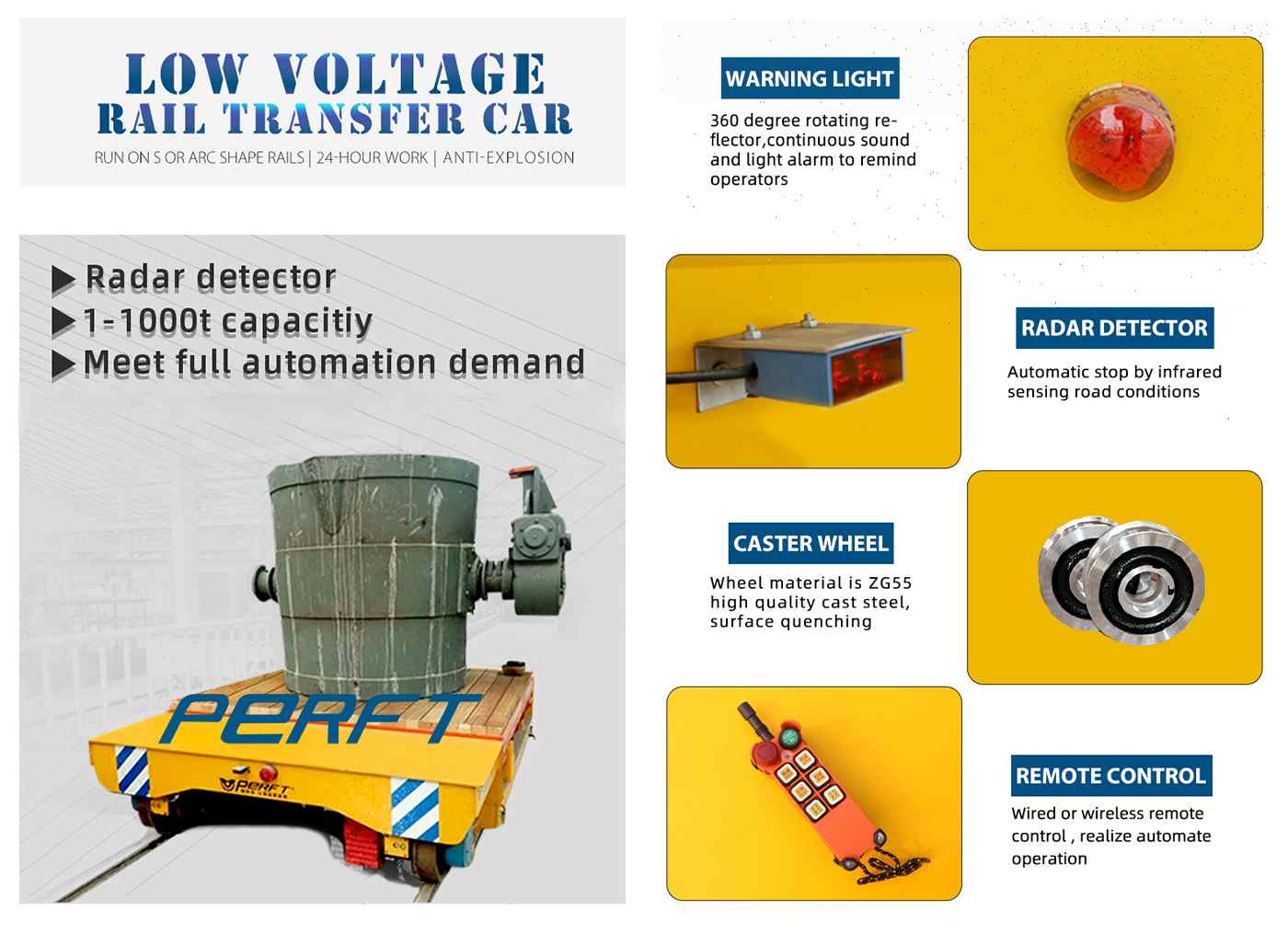

◆ Running on s and arc-shaped rails

◆ Curved track mounted ◆ Special design turning driving system

◆ Motor with braking function

◆ Widely applied to transfer ladle bucket, heat resistance

◆ Suitable for flammable environment

Rail Transfer Cart Noise During Operation

- Electrical control cabinet failure: Most contactors of transporter trolley usually make noise when they fail. Contactor failure should be maintained in time. If it cannot be maintained, it must be replaced. After processing, the noise will disappear by itself.

- Rail transfer cart failure: First stop industrial carts and check whether the bearing is damaged. This will cause electric transfer cart to produce abnormal sounds. The sound height and volume vary depending on the fault. When running, the whole transfer car will make regular noises.

- Reducer failure: First determine whether the gears and bearings of the reducer are lubricated before use and whether the lubricating oil is replaced regularly. Without adding lubrication, the reducer of rail cart will produce excessive humming noise and excessively damage the gears and bearings.

Rail Transfer Cart No Power Display

- No power: Whether the electrical system is powered by the power supply, generally use a test pen to test, no power, and then work after power is supplied.

- Voltage is too low: The voltage at the input end of rail transfer trolley is more than 10% lower than the rated voltage, and the starting torque is too small, so that transfer trolley cannot move.

Overuse of Rail Transfer Cart

- Overload: Overload will make electric cart heat up, and long-term overload will burn electric transfer cart, so the load of rail transfer cart must be within the rated load range.

- Bearing damage: Replace the bearing

- Unspecified working system: Strictly follow the working system when using.

Technical Parameters of Rail Transfer Cart

| Model | BDGS-2t | BDGS-5t | BDGS-10t | BDGS-20t | BDGS-30t | BDGS-40t | BDGS-50t | BDGS-80t | BDGS-100t | |

| Rated Load (t) | 2 | 5 | 10 | 20 | 30 | 40 | 50 | 80 | 100 | |

| Table Size (mm) | Length | 2000 | 3500 | 3600 | 4000 | 4500 | 5000 | 5500 | 6000 | 6500 |

| Width | 1500 | 2000 | 2000 | 2200 | 2200 | 2500 | 2500 | 2600 | 2800 | |

| Height | 450 | 450 | 500 | 550 | 600 | 650 | 650 | 800 | 850 | |

| Wheel Base (mm) | 1200 | 2500 | 2600 | 2800 | 3200 | 3800 | 4200 | 4700 | 4900 | |

| Rail Inner Gauge (mm) | 1200 | 1435 | 1435 | 1435 | 1435 | 1435 | 1435 | 1800 | 2000 | |

| Wheel Diameter (mm) | Ф270 | Ф270 | Ф300 | Ф350 | Ф400 | Ф500 | Ф500 | Ф600 | Ф600 | |

| Wheel Quantity | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | |

| Ground Clearance (mm) | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 75 | 75 | |

| Running Speed (m/min) | 0-25 | 0-25 | 0-25 | 0-20 | 0-20 | 0-20 | 0-20 | 0-20 | 0-20 | |

| Motor Power (Kw) | 0.8 | 0.8 | 1.5 | 2.5 | 4 | 5.5 | 5.5 | 7.5 | 11 | |

| Transformer Power(KVA) | 3 | 3 | 5 | 6.8 | 10 | 10 | 10 | 20 | 30 | |

| Transformer Quantity | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | |

| Running Distance (m) | 70 | 70 | 70 | 70 | 70 | 60 | 50 | 50 | 50 | |

| Max Wheel Load( kn) | 14.4 | 25.8 | 42.6 | 77.7 | 110.4 | 142.8 | 174 | 278.4 | 343.8 | |

| Recommended Rail Model | P15 | P18 | P18 | P24 | P38 | P43 | P43 | P50 | QU100 | |

How to Maintain Rail Transfer Cart

Rail transfer cart needs regular maintenance, adding lubricating oil, checking electrical appliances, button sensitivity, etc., and regularly checking the insulation of the wheels and the wear of the carbon brushes.

Regularly check whether the internal parts of the transfer cart on rail motor are deformed, the surface condition of the commutator, and the wear of the brushes. Maintenance should be carried out in time before resuming work.

Every six months (the inspection cycle should be shortened if the low voltage rail transfer cart is in frequent and complex operation), check at least once according to the following methods.

a: Remove dirt, dust, and carbon deposits from the motor to ensure normal operation of motorized transfer trolley.

b: Clean or replace the bearings, and add 3# lithium-based grease to the raceway after cleaning.

c: According to the wear of the brushes, replace them in a professional maintenance unit in time. After replacing the new carbon brushes, ensure that the running-in arc surface is not less than 70% before putting them into operation.