Trackless Electric Transfer Carts: 4 Key Aspects You Should Know

Trackless electric transport cart is different from other electric handling equipment. First of all, it is a driving environment without laying rails. Secondly, it is an electric-driven cart that automatically drives under the drive of the motor reducer. The polyurethane wheels used in steerable transfer carts will not cause damage to the ground. There is no steering wheel on the body, only forward or backward, and it can make turns without a dead angle of 360 degrees. When encountering people and objects, trackless transfer cart can be prevented by warning lights, parking devices, reducers, and other safety devices.

Body Structure of Battery Powered Transfer Cart

The frame structure of steerable industrial transport cart is a box-shaped structure formed by the integral welding of longitudinal beams, several cross beams, and the work surface cover. This structure is paired and combined with the bearing seat on the wheelset, which effectively reduces the height of the platform and improves the force of the frame.

The work platform of motorized transfer cart is equipped with a detachable inspection hole, and there are four lifting holes or hooks on both sides of the frame for lifting and turning. The longitudinal beams and cross beams of the frame are combined in the form of I-beams and channel steels of the same size, and the work surface is made of high-quality carbon steel plates. The strength of the frame is designed according to 1.25 times the rated load, to ensure that the frame will not deform when loaded with a certain heavy load.

Drive Device of Steerable Transfer Cart

- Maintenance-free battery. Generally installed on the bottom of motorized transfer cart, it consists of one or more battery cells, each of which contains a positive electrode, a negative electrode, and an electrolyte. When the battery is in a discharged state, a chemical reaction occurs between the positive and negative electrodes, generating a current and releasing the stored energy. When the battery needs to be charged, the current flows in the opposite direction, reversing the chemical reaction and restoring the energy.

- High-quality motor, strong power. Heavy duty transfer trolley uses a DC traction motor. The motor has adjustable speed, low energy loss, easy control, large starting and braking torque, and strong overload capacity.

- The reducer adopts the heavy-duty standard of lifting and transportation industry and is specially designed for hardened flat cars. It has a compact structure, high reliability, good versatility, easy to install and maintain. The gears are carburized, quenched, and ground.

Angle Box Wheel of Material Handling Equipment

Includes angle box, heavy-duty bearing, and wheel. The axle of the wheel body is inserted into the heavy-duty bearing inside the angle box. The g-shaped clamp is provided on the outside of the angle box mounting plate. Reinforcing rib is provided at the connection between the angle box and the angle box mounting plate.

The utility model changes the original medium-duty bearing into a heavy-duty bearing, and at the same time improves the angle box, increases the load-bearing capacity of the wheel, can resist the instantaneous excessive load generated when the steel plate is turned over during driving, increases the service life of the wheel, reduces unplanned downtime, ensures smooth production, and reduces spare parts costs and labor maintenance costs.

Safety Settings of Industrial Transport Cart

Because trackless transfer cart is different from rail transport cart in that there is no rail and no preset path, in this case, electric transfer cart is equipped with:

- Scanning radar to sense the road conditions. If there is an obstacle in front, battery operated transfer cart will stop automatically. We use primary laser and multi-echo technology, IP67 protection level, and an internal integrated heater, and can set ten protection areas.

- At the same time, we also install bumpers on trackless transfer carts, which are fixed on the front and back and both sides of the cart body in the form of rubber bumpers, to reduce the impact and stop the vehicle after touching.

- Emergency button: The button is located on both sides of electric transfer cart, on the power box, and the operating handle. As long as one of them is closed, trackless transfer cart will stop running immediately.

Trackless electric transfer cart is a type of factory material handling tool that has developed rapidly in recent years. It breaks the rule that electric rail flat cars cannot turn in a small radius and broadens the scope of use. Trackless electric transfer carts are a kind of wheeled handling equipment that can be turned arbitrarily through manual control. BWP trackless electric transfer cart produced by our factory can transport large tonnage of materials. This series of electric transfer trolleys not only can be used for industrial transportation but also can work in special environments and non-fixed places, helping you solve the problem of heavy-duty work.

20 Ton Trackless Transfer Cart Video

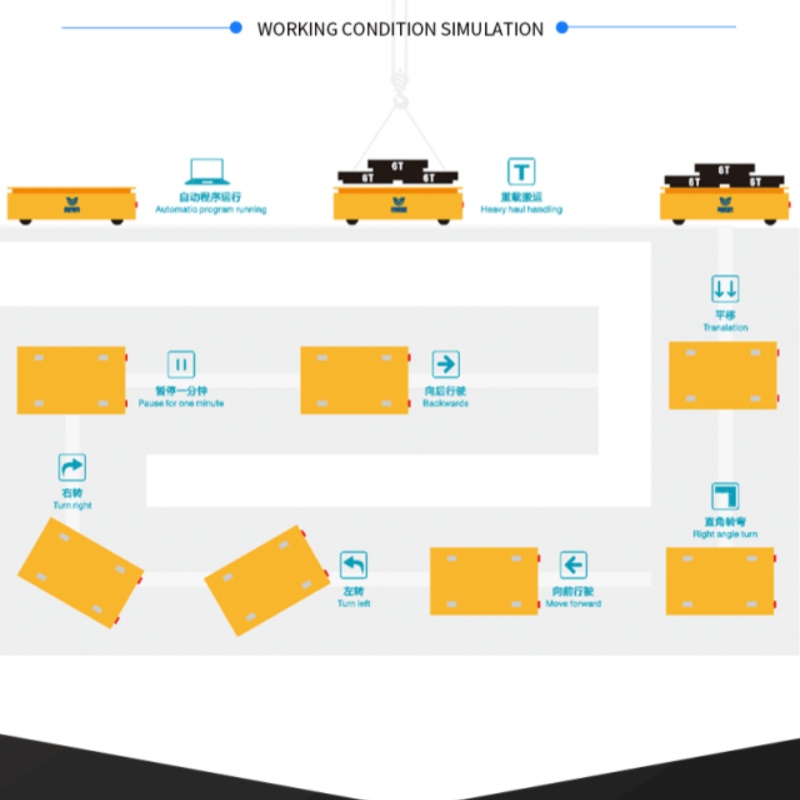

Battery powered trackless transfer cart can be operated forward, backward, or turn by wireless remote control, buttons, or PLC system.